Taiwan Proposes Building a Democratic Supply Chain Amidst Geopolitical Challenges

Will Trump Listen? Or Continues Bashing TSMC for His MAGA Dream?

On Friday, Taiwan’s President Lai Ching-te hosted a National Security Meeting with his cabinet and proposed a “Global Democratic Semiconductor Supply Chain Initiative” (GDSSCI) in a press conference after the meeting.

Lai did not provide specific details of the GDSSCI but emphasized that Taiwan aims to collaborate with the U.S. and other democratic allies to build a robust and diverse semiconductor supply chain, leveraging advanced semiconductors to form a global AI chip industry alliance and a democratic supply chain for high-end chips. According to Lai, this initiative would ensure industries in democratic nations have access to high-end chips and open a new era for the international semiconductor industry.

“As the Trump administration enacts new policies, we'll maintain close communication with the US government, emphasizing Taiwan's crucial role in America's manufacturing resurgence and high-tech dominance, fostering a mutually beneficial partnership,” said Lai. Taiwan intends to highlight that bilateral cooperation is mutually beneficial, communicating and negotiating closely with Washington to reinforce Taiwan as an indispensable partner in rebuilding U.S. manufacturing and consolidating technological leadership.

The GDSSCI represents a bold vision for a more secure and resilient semiconductor supply chain among democratic nations. However, will President Trump listen? He is busy getting TSMC technology to help advanced chips produced in America, and perhaps preferably by Intel.

Recently, discussions have emerged about whether TSMC’s potential collaboration with Intel in the U.S. could lead to a situation similar to past geopolitical conflicts. However, TSMC possesses strong capabilities in protecting its technology, a strength that should not be underestimated. If reverse engineering alone—merely analyzing a chip’s structure and adjusting process parameters—were enough to achieve successful mass production, then semiconductor manufacturing would not be the formidable challenge it is today. “As a company that Taiwan takes immense pride in, we believe TSMC will undoubtedly find the best balance between its commitments in the U.S. and Taiwan, ensuring its continued leadership in the global semiconductor industry,” wrote SemiVision analysts.

Global Democratic Semiconductor Supply Chain Initiative

Hinging all the hope on TSMC may not be realistic, because no matter how perfect the plans may be designed to get TSMC to bail out Intel, they are unlikely to get approval from China for anti-trust reviews even if all other countries give greenlights.

Besides, it takes more than TSMC to foster a healthy semiconductor supply chain for the world.

What can this “Global Democratic Semiconductor Supply Chain Initiative” be like? What will be the challenges?

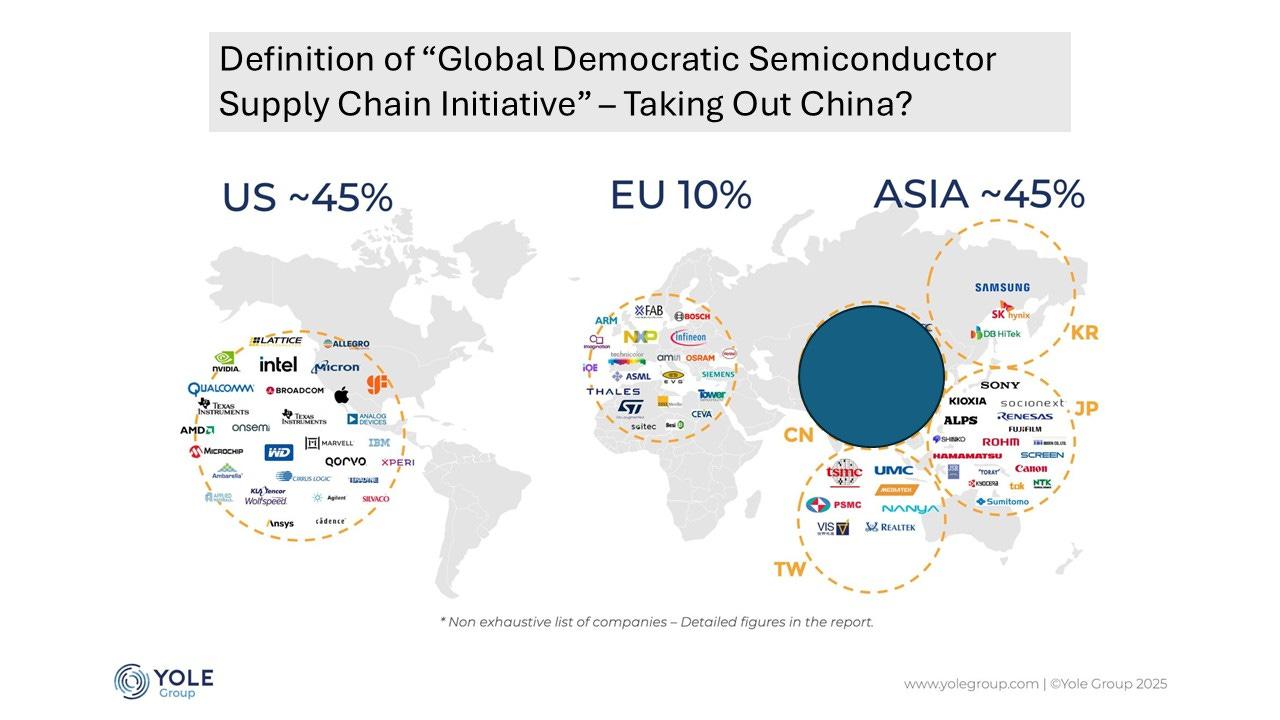

Let’s borrow Yole’s diagram to explain the current state of the global semiconductor supply chain:

If the democratic supply chain is to be formed only among the democratic countries, that means blotting out China (see diagram). If China’s ultimate goal for Made in China 2025 was to achieve “self-sufficiency”, maybe this is the time for that dream to come true or prove unrealistic.

GDSSCI: Challenges and Possibilities:

Democratic country companies still selling their chips, materials, and equipment to China, need to prepare for potential countermeasures from Beijing if it decides to boycott their products. After all, China remains the largest semiconductor importer9. In 2024, China’s chip imports surged 10.4% to US$385 billion amid tighter US tech sanctions, reported by SCMP. China imported a total of 549.2 billion ICs in 2024, a 14.6% increase from a year earlier, according to data published on Monday by the General Administration of Customs. To exclude China from the supply option also means losing that giant market. The GDSSCI must create a market big enough to make their operations sustainable.

Are the United States and European Union economies strong enough to absorb that supply? Developing domestic markets in Southeast Asia and India, where young middle classes are growing, could also help. However, since many American and European semiconductor companies depend on the Chinese market, reducing their reliance could mean losing a significant portion of their sales. This would be a painful transition if new electronics production sites elsewhere can't provide sufficient demand for chips.

Following the Trend, Not Reversing It:

An ecosystem in the biological world is a full cycle of the food chain. Therefore, a semiconductor supply chain cannot thrive on only advanced or legacy chips; both are important. Democratic countries possess all these components.

Why did the global semiconductor supply chain evolve this way after four decades instead of being dominated by a single country? Companies have a natural incentive to increase profits. When companies in the United States found it difficult to recruit enough engineers for fabs or to produce with better cost efficiency, they chose to outsource manufacturing to overseas fabs with good quality and yields, focusing on chip design and product development. This is how AMD thrived and strengthened its competitiveness against Intel.

Can you blame the overseas fabs for serving their customers in the United States? Can you blame the American chip companies that wanted to optimize their shareholders’ equity? They are just optimizing the efficiency of operations for the benefit of their customers and their shareholders.

Semiconductors are a very complex industry and require a delicate division of labor. “There is no need for a single country to have complete control or monopoly over all the technologies, as this would not be optimally cost-effective,” commented Cheng-wen Wu, the Minister of Taiwan’s National Council of Science and Technology, who is a semiconductor expert himself.

For over 40 years, no single country has been successful in keeping all the components of the semiconductor supply chain together under its roof, not even Taiwan, Japan, or Korea. Not even America, how would China be able to do that?

Therefore, it will be futile to try to reverse that evolution. Going with the trend to make efforts in diversifying the supply chain to Japan, America, Europe, Southeast Asia, and India is good for resilience. However, sound infrastructure and ecosystems are needed locally for manufacturing. Talents are the most needed assets.

For example, if America wants to get the semiconductor manufacturing work back, they must ensure that sufficient workers are willing to do the monotonous, high-precision fab job that requires them to wear plastic bunny suits for at least 8 hours. Can robots replace manpower to do the production line work? Perhaps. However, they still need human engineers to fine-tune the equipment ready for that operation. According to past experiences, the equipment is very sensitive, any change in the environment, such as humidity, temperature, or even cow fart in nearby farms will affect its precision. Are American engineers willing to return to the fabs to deal with those irregularities and ensure smooth production of the foundry?

“The core of semiconductor manufacturing lies in its process parameters. Key processes such as photolithography, thin film deposition, etching, and diffusion all play a crucial role in determining chip yield” SemiVision analysts explained. “For a foundry to enhance its yield rates, it relies on the relentless efforts of engineers at every station to fine-tune process recipes to their optimal state.”

The Semiconductor Industry Association also pointed out the challenges and recommended policies to adapt for the United States.

However, since other global competitors also continue to invest in their semiconductor ecosystems and advance their technological capabilities, they will compete for talent.

Additional Considerations:

China remains a pivotal player in global supply chains, including semiconductors. What may be the consequences of leaving out China for the global semiconductor supply chain?

Rare Earth Elements: Since China dominates the supply of rare earth elements, excluding it from the supply chain means the democratic world will need to find alternatives quickly.

Manufacturing Hub: China remains the world's largest manufacturing hub. Is it possible to require all the chips used in products assembled and built in China to be “democratic”? It may be more feasible for assembly facilities outside China to do so. However, can China’s supply chains be completely replaced? There are already reports that China is making it more difficult for companies like Foxconn to shift equipment from China to India.

Geopolitical Factors: If Trump brokers a peace accord with Russia and Ukraine and secures resources from Eastern Ukraine as an alternative source to counter China, and Russia is heavily dependent on China, why would Russia listen to Trump?

Oversupply vs Shortage: China’s massive construction of dozens of fabs has created an oversupply that made it even tougher for legacy chip makers and DRAM companies that are already facing the challenge of weak demand. If China’s supply is to be boycotted by the democratic world, will an oversupply suddenly become a shortage?

The initiative will require careful navigation of geopolitical realities, economic incentives, and technological capabilities. Success hinges on fostering genuine collaboration, strategic investments, and a commitment to addressing the inherent challenges of reshaping a globalized industry

President Lai’s grand vision is going a long way. This is consistent with the new state department’s relationship with the country announced on Sunday. Friends come together because of similar value and like minds, not by coercive force. Unfortunately, more than 1.4 billion people didn’t get this due to fake education.

Taiwan is a fast learner of American-Euphemism 🤣 Unlike the FAKE-Democracy of G7, the MOST DEMOCRATIC supply chain lies in BRICS.😉